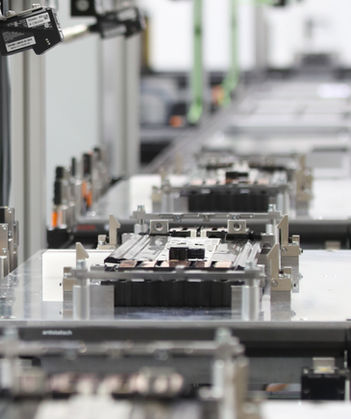

Gripping and Handling Systems

Handlers and grippers are handling systems that are used in a variety of applications to safely grip, quickly move and precisely position objects. In conjunction with robots and other automation technologies, they have revolutionized production processes in many industries. As an essential component of modern production systems, they relieve the human workload, prevent errors and enable short cycle times, efficiency and high productivity with consistently reproducible results.

Our Systems Make the Difference

There are several reasons why we think it makes sense to design handling and gripping systems ourselves as part of automation and to produce them in-house. By using high-quality materials, we are able to produce systems that are particularly durable and reliable, as well as adapted to the specific requirements of a wide range of product variants.

We have extensive expertise and experience in the field of gripper construction, which we have acquired in numerous collaborations with our customers on a variety of handling tasks. In this way, we not only bundle the necessary resources and skills to deliver and install grippers quickly, but also to provide support in the event of accidents and product adjustments.

Areas of Application & Expertise:

-

Tool loading (inserting metal cores, grids, contacts, bushings or sleeves into injection molding tools)

-

Removing and aligning components from injection molding tools (single and multiple tools)

-

Stamping and bending handling for plug contacts, incl. reels

-

Pick & place applications with parallel component processing and testing

-

Shape-specific fixtures for various components (e.g. covers, housings, foil circuit boards, screen mesh)